ISO 9001:2015 QUALITY MANAGEMENT SYSTEM

Drive down costs, increase productivity and boost customer satisfaction.

ISO 9001 certification assists even the smallest businesses in demonstrating the quality of their processes, while simultaneously driving down costs, improving productivity and boosting customer satisfaction.

The ISO 9001 Quality Management System can be implemented by both large and small businesses, offering a whole range of benefits to your company. What's more, by following our market-leading four stage process, gaining certification is simple and fast. In many cases, ISO 9001 certification can be achieved in under 30 days, saving your business a great deal of time and money!

The ISO 9001 Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO 9001 compliant manual, which can be done by one of our experienced consultants, or by yourself using a our template.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Your dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO 9001 certification, an accredited auditor must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

Open New Markets and Pitch for New Business

ISO 9001 Certification can make the crucial difference when it comes to entering new markets, competitive industry sectors and when bidding for tenders or contracts. ISO 9001 certification opens up new markets and is often a prerequisite when tendering for government and blue chip contracts, with certified Organisations awarded points in pre-qualification questionnaires (PQQ’s). Furthermore, a recent survey revealed that, as a result of gaining the ISO 9001 certification, organisations experience a significant increase in sales.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 14001:2015 ENVIRONMENT MANAGEMENT SYSTEM

Reduce your environmental impact, increase customer trust & meet legal obligations.

The ISO 14001 environmental management system allows organisations to demonstrate to stakeholders and customers that the business is committed to reducing its environmental impact, as well as reducing costs associated with waste management.

The ISO 14001 standard was developed in 1996 with the aim of helping companies comply with regulations and laws, and improve their environmental impact. ISO 14001 is one of the most popular standards in the world, as it applies to all sectors of business, and organisations of any size.

The Benefits of ISO 14001

With customers, regulators and the government putting greater pressure on businesses to reduce their environmental impact, our ISO 14001 consultants help address the fundamental areas to prepare you for future changes in environmental legislation and improving your environmental reputation.

By streamlining processes with an environmental management system your company will stand out, and in turn increase sales. What's more, savings can be made within your business by addressing areas such as waste, energy and water consumption.

ISO 14001 Certification Process

At MMC, we make the certification process quick and simple with our unique four step process. The first stage to ISO 14001 certification is to draft an ISO compliant manual, which can be done by a MMC consultant, or by yourself using a MMC template. Next comes stage two: implementation. Your ISO manual must be brought into use within your organisation, with MMC guiding you on how best to do this.

Stage three is the ISO 14001 certification stage. To gain certification, an accredited auditor must visit your company and check that the processes documented in your manual are being followed. Finally, to ensure your certification remains valid, you must have your processes and manual checked each year by your accredited ISO certification body.For further advice on your requirements or to get your instant quotation, please call us on +965 25712190.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

OHSAS 18001:2007 HEALTH & SAFETY MANAGEMENT SYSTEM

Control health and safety risks, protect employees and meet legal obligations.

OHSAS 18001 stands for Occupational Health and Safety Management Standard, and by becoming certified companies are able to identify and control the management of health & safety risks.

OHSAS 18001 certification allows your business to demonstrate that a health and safety management system is in place to reduce the likelihood of accidents, prevent breaches of legislation and improve your organisation's overall performance. By gaining certification employee, customer and stakeholder confidence is increased, in turn enhancing your company's reputation and allowing you to stand our amongst competitors.

OHSAS 18001 Management System

At MMC we have a smooth OHSAS 18001 accreditation process that allows you to become certified in just 30 days. Initially we will need to spend a day or two on site assessing your current situation. At the next stage you will be issued with a gap analysis which highlights any areas needing rectifying in relation to where the standard requires you to be. Once the OHSAS 18001 management system is implemented then certification is usually possible within a few weeks.

Health and safety standards apply to all industries, and the OHSAS 18001 standard is suited to businesses big or small, from the public or private sector. It is a way of demonstrating your company's dedication to lowering health and safety risks, and in turn reducing costly disruptions to your business.

Less disruptions and lowered risk of accidents and incidents in turn increases the productivity of your company. OHSAS 18001 certification will also mean that you have the systems in place to ensure you are compliant with the latest health and safety information, therefore minimising the risk of legal action.

OHSAS 18001 Certification Cost

Through MMC, you can achieve OHSAS 18001 cost-effective certification quickly and simply thanks to our industry-leading four stage certification process. This hassle-free process is designed to save your company a great deal of time and money.

The cost of OHSAS 18001 certification depends on several factors, and varies based on total staff, nature of activities and number of locations.

To find out how to get started, further advice on your requirements, or for an instant quote, call us on +965 25712190.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 22000:2005 / HACCP FOOD SAFETY MANAGEMENT SYSTEM

Reduce food risks & improve food safety in line with Codex HACCP Principles.

ISO 22000 Certification improves communication along the food supply chain, complies with Codex HACCP Principles and is approved by regulators. It delivers a food safety management system that ensures the end product delivered to the consumer is of a high standard and free from contamination.

ISO 22000 Standard

By choosing MMC to help you with your consultancy, certification and support needs, you will be provided with a Food Safety Management System that covers all aspects of the food supply chain, is easy to implement, causes minimal disruption to your organisation and can be obtained in under 30 days through our4 Stage Certification Process.

The ISO 22000 standard can give you a competitive advantage, helping you stand out from your competitors, opening up new markets. By becoming ISO 22000 certified you are demonstrating your food safety commitments to stakeholders and any interested parties, with the standard being approved by regulators and complying with Codex HACCP Principles; in turn enhancing your reputation.

Food Safety Management

If food related diseases get into your food supply chain it can be devastating, not only because you could face fines but your reputation could become severely damaged. ISO 22000 puts the systems in place to minimise these risk.

The principles of ISO 22000 will introduce internationally recognized processes into your business, ensuring you will have the right hazard controls in place, introducing transparency and accountability for responsibilities.

ISO 22000 Certification

Organisations certified through MMC also have the added benefit of accessing the online MMC client portal. For further advice on your requirements or an instant quotation call us on +965 25712190.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 20000-1 IT SERVICE MANAGEMENT SYSTEM

Attain the highest standard of internal and outsourced IT service delivery.

ISO 20000 certification helps organisations to provide the highest standard of internal or outsourced IT services, with a management system that ensures robustness, efficiency and responsiveness. Sometimes referred to as ITSM, this certification is well renowned as a quality management system of processes and procedures surrounding all areas of IT.

ISO 20000 Overview

By becoming ISO 20000 certified through MMC, your IT processes will be aligned with aspects of the ITIL approach, from the Office of Government Commerce (OGC), and you will receive an IT Management System that will cause minimal disruption to your Organisation, is competitively priced and can be achieved in under 30 days through our 4 Stage Certification Process.

ISO 20000 Standard

Below is an ISO 20000 checklist of the benefits which becoming certified offers your business.

Improved IT Service - ISO 20000 certification ensures that organisations can achieve evidence-based benchmarks to continuously improve the delivery of their IT services.

Competitive Advantage - Having an IT Service Management System in place will enable your organisation to stand out from competitors because the system demonstrates that you follow international best-practice procedures.

Improved Management Of External Suppliers - The Standard delivers a framework that ensures you get the most out of your external IT suppliers. Giving you greater confidence and improving your reputation.

Reduced IT Costs - By having a more effective IT Service Management System, you can help drive the cost of IT and related services down.

Enhanced Reputation - ISO 20000 certification provides independent proof that you instil good practises and are committed to an IT Service Management System that will deliver service excellence.

ISO 20000 Certification

After you've gained this certification with MMC, you will have access to ongoing support and consultancy services that will assist you with the management of your ISO 20000 Certification.

Getting Started to find out how to get started, further advice on your requirements, or for an instant quote, call us on +965 25724044.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 27001:2013 INFORMATION SECURITY MANAGEMENT SYSTEM

Protect corporate information and data, manage threats and gain customer confidence.

ISO 27001 certification demonstrates that your business has systems in place to protect corporate information and data. By gaining ISO 27001 customer and stakeholder confidence is increased, and your company's reputation is improved, allowing you to stand out amongst competitors.

ISO 27001 Overview

By becoming ISO 27001 certified companies are showing a commitment to ensuring that adequate security controls are in place to protect information and data from being accessed, corrupted, lost or stolen.

ISO 27001 certification demonstrates your compliance with internationally recognised standards of information security. Becoming certified with MMC is simple and hassle-free, with our 4 Stage Process, and can be achieved in under 30 days, saving your business time and money.

The ISO 27001 Certification Process

At MMC we have a team of over 20 consultants nationwide with many years of experience. By spending just a short amount of time on site our consultants are able to draft an ISO compliant manual for your business.

The next stage is implementation. At MMC we will happily advise how best to bring your ISO 27001 manual into use within your organisation. Stage 3 is certification. The ISO 27001 accreditation is completed with a visit by an accredited auditor to your company to ensure that the processes documented in your manual are in place, and being followed correctly.

The fourth and final stage is surveillance. Your manual and processes must be checked annually to ensure that you ISO 27001 remains valid.

Benefits of ISO 27001

By gaining ISO 27001 certification in information security management you are showing that you have processes in place to effectively protecting corporate information within your company. This will put you in a competitive position when bidding for new contracts or tenders. ISO 27001 will mean you stand out amongst competitors and can make the crucial difference when entering competitive industries and new sectors.

Getting Started to find out how to get started, further advice on your requirements, or for an instant quote, call us on +965 25712190.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 22301 BUSINESS CONTINUITY MANAGEMENT SYSTEM

Maintain business through disruptive times, keeping revenue and reputation intact.

With the future becoming more volatile, it’s essential that organisations are prepared for the worst. An effective business continuity management system will enable your organisation to develop a best practice approach for reducing disruptions, when continued operation is vital.

What is ISO 22301?

ISO 22301 certification from MMC will help your organisations to prepare for, respond to and recover from disruptive events when they arise, ensuring that customers and suppliers are not affected, so that revenue and reputation are sustained.

Gaining certification will give you a competitive advantage. Through the universal acceptance of the ISO 22301 standard you will gain customer confidence, giving you a competitive advantage and helping you enter new markets.

Benefits of the ISO 22301 Standard

Rapid recovery - Whether it’s a natural disaster or minor disruption, with the business continuity ISO 22301 your organisation will be robust enough to recuperate quickly; managing disruptions, so that usual processes can resume.

What's more, through regular audits and by ensuring your business continuity management system stays up-to-date you will be able to monitor performance, gaining a clearer understanding of your organisation and easily identifying areas for improvement.

ISO 22301 also offers cost savings - having a business continuity management system in place will assist you in recuperating quickly, reducing the likelihood of financial loss and lowering insurance premiums. What's more gaining certification will give you peace of mind - 81% of managers with ISO 22301 in place agreed that it successfully reduced disruption and was worth the cost due to the benefits that it brought to their company. This standard provides a framework that organisations can fall back on at times of crisis.

ISO 22301 certification

In addition to providing a route to certification, MMC also offer support and consultancy services to assist you with the development, implementation and management of your Business Continuity Management System and Manual - making ISO 22301 Certification affordable and easy to implement.For further advice on your requirements or an instant quotation call us on +965 25712190

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 31000 RISK MANAGEMENT SYSTEM

Embed risk management in to every aspect of your business.

ISO 31000 is a risk management system which ensures your business can mitigate risks by identifying threats. This standard delivers international best practice that will improve decision making processes and management techniques within your company.

The ISO 31000 risk management standard can safeguard your business, and gaining certification will increase customer and stakeholder confidence, and mean that your company's reputation is improved; allowing you to stand out amongst competitors. ISO 31000 certification sends out a clear message that you are committed to managing risks in every aspect of your business.

This standard delivers international best practice techniques that will improve decision making processes as well as management techniques within your organisation. By implementing ISO 31000 risk management framework within your company you will gain the peace of mind that potential risks have been assessed and mitigated. You can reduce the likelihood of incidents occurring and the financial losses that come with them.

The ISO 31000 Certification Process

The ISO 31000 standard is suited to companies in the public or private sector, from sole traders right through to multinational organisations. By having an effective risk management system in place you can reduce the likelihood of incidents occurring, and the financial losses that are associated with them.

Using our industry-leading four stage process means certification can be achieved in under 30 days. This process is simple and hassle-free, designed to save your business time and money. At stage 1 you work with MMC to draft your ISO 31000 manual - this can be done by an experienced consultant, or by yourself using a MMC templates.

The next stage is implementation, whereby the practices outlined within your manual must be bought into use within your organisation. At stage 3, to gain ISO 31000 certification, an accredited auditor must visit your company to check and assess that processes documented in the manual are being followed. Finally, stage 4 is surveillance - an annual check will ensure your ISO certification remains valid.

Getting Started

To find out how to get started, further advice on your requirements, or for an instant quote, call us on +965 25712190.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 50001 ENERGY MANAGEMENT SYSTEM

Improve energy performance, efficiency and consumption.

ISO 50001 certification in energy management demonstrates that your business has systems in place for establishing and maintaining best practice when it comes to energy performance, consumption and efficiency. By gaining ISO 50001 certification customer and stakeholder confidence is increased, and your company's reputation is improved, allowing you to stand out amongst competitors. ISO 50001 certification sends out a clear message that you are committed to reducing your environmental impact.

ISO 50001 Overview

The ISO 50001 standard is suited to companies in the public or private sector, from sole traders right through to multinational organisations. It is a way of demonstrating your company's dedication to lowering your energy consumptions, and in turn your carbon emissions.

The nature of ISO 50001 means that you will see savings in the long run. By evaluating where you waste energy and helping you to reduce consumption, ISO 50001 will in turn reduce your energy bills.

Not only can this enhance reputation and save money, but gaining ISO 50001 certification will mean you are at the forefront of the latest opportunities. Renewable energy technology is always developing and by being in-the-know you can improve performance within your organisation.

ISO 50001 ensures your business complies with current environmental legislation, including the latest greenhouse gas (GHG) legislation. It also helps you to adapt to any future changes in carbon taxes or law changes.

The ISO 50001 Certification Process

Becoming certified with MMC is simple and hassle-free, with our market-leading 4 Stage Process, and can be achieved in under 30 days, saving your business time and money. Our team of over 30 consultants nationwide have many years of experience and by spending just a short amount of time on site our consultants are able to draft an ISO compliant manual for your company.

Once drafted at stage one, your manual is then bought into use within your organisation at stage 2, and at MMC we will happily advise on best practices for this. Stage 3 is certification, where an ISO 50001 accredited auditor will visit your company to ensure that the processes documented in your manual are being followed. The fourth and final stage is surveillance. Your manual and processes must be checked annually to ensure that you ISO certification remains valid.

Getting Started to find out how to get started, further advice on your requirements, or for an instant quote, call us on +965 25712190.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 55001 ASSET MANAGEMENT SYSTEM

Pro-actively manage the lifecycle of assets, from acquisition to decommission.

ISO 55001 is a framework for an asset management system that will help your business pro-actively manage the lifecycle of its assets, from acquisition to decommission. This system helps you manage the risks and costs associated with owning assets, in a structured, efficient manner that supports continual improvement and on-going value creation.

ISO 55001 Certification

Your business could gain ISO 55001 certification with MMC in under 30 days by using our simple, hassle-free 4 stage certification process. At stage one an experienced MMC consultant will draft your ISO 55001 manual. Next, at stage two your new ISO manual must be bought into use within your organisation. At stage three an accredited auditor must visit your company to check that the documented processes in the manual are being followed. At this point certification is awarded. Stage four is surveillance, whereby annual checks are made to ensure your certification remains valid, and that documented processes continue to be practiced.

What Is Asset Management?

ISO 55001 is part of the ISO 55000 'family' of standards. ISO 55000:2014 can be applied to all types of assets. This asset management system is suitable for all sizes of company, and all types of business. It is a framework which manages all aspects of assets, and it offers a range of benefits including:

Reducing risks: risks associated with the ownership of assets – anything from unnecessary maintenance costs and inefficiency to accident prevention (explosions at gas plants for example) are reduced.

Improved quality assurance: for customers/regulators – where assets play a key role in the provision and quality of products and services, ISO 55001 can improve quality assurance.

New business acquisition: stakeholders gain confidence from the knowledge that a strategy is in place to ensure assets meet the necessary safety and performance requirements. ISO 55001 enhances business reputation which can lead to gains in new business.

Supports international business growth: demonstrating that the requirements of an internationally recognised asset management system are being met with ISO 55001 certification can give your company a competitive edge, and encourage growth.

For further advice on your requirements or an instant quotation call us on +965 25712190.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

ISO 17025 LABORATORY MANAGEMENT SYSTEM

ISO 17025 was written to incorporate all the ISO 9001 requirements that are relevant to the scope of testing and calibration services as well as specifying the technical requirements for technical competence.

Testing and calibration laboratories that comply with ISO 17025 will also operate in accordance with ISO 9001.

The Contents of ISO 17025

The ISO 17025 standard itself is comprised of 5 elements:

- Scope

- Normative References

- Terms and Definitions

- Management Requirements

- Technical Requirements

Elements 4 and 5 contain the actual accreditation requirements.

Accreditation Requirements

Management Requirements

- Organization

- Quality system

- Document control

- Review of requests, tenders and contracts

- Subcontracting of tests and calibrations

- Purchasing services and supplies

- Service to client

- Complaints

- Control of nonconforming testing and/or calibration work

- Corrective action

- Preventive action

- Control of records

- Internal audits

- Management reviews

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

Pre-Start Health & Safety Reviews (PHSRs)

A Pre-Start Health and Safety Review is required to be performed as per Section 7 of Regulation 851, R.R.O. 1990 under the Occupational Health and Safety Act R.S.O, 1990 which states that a new apparatus, structure or protective element is to be constructed, added or installed or a new process at your plant must be reviewed by a Professional Engineer to ensure compliance with the applicable codes and safety standards.

What is a Pre-Start Health and Safety Review (PHSR)?

Prior to any worker being permitted to operate any machinery, equipment, or a process in a hazardous environment, an employer is responsible for ensuring that a thorough report is prepared that shows that the equipment is safe. This PHSR report is required to review all of the relevant regulations pertaining to that particular type of equipment.

Where in the workplace do PHSRs apply?

PHSRs must be completed when:

a new “apparatus”, structure, or “protective element” is to be constructed, added or installed, or a new process is to be used; or an existing “apparatus”, structure, “protective element”, or process is to be modified and to comply with applicable provisions whereby either:

new or modified engineering controls are used

other new or modified measures are used, or

a combination of new, existing or modified engineering controls and other new or modified measures are used.

Who can perform a PHSR?

As mandated by the OHSA, the review must be conducted by a Professional Engineer (licensed by the province) that possesses special expert or professional knowledge or qualifications.

Is a PHSR review always required?

Pre-Start Health and Safety review is mandatory to ensure that the design & control requirements for electrical, mechanical, pneumatic or hydraulic systems are met. The purpose of the review is to identify and eliminate hazards by reliable control using proper safety devices.

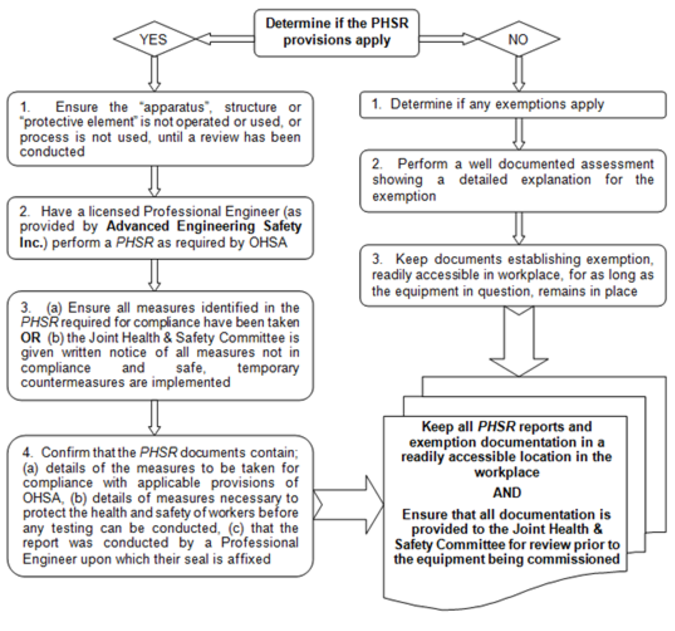

As outlined by the regulations in the OHSA, there are certain exceptions whereby a PHSR conducted by a Professional Engineer is not required. In such situations, the employer is responsible for ensuring that an exemption is properly completed. This includes keeping and maintaining documents establishing the exemption, and making them readily accessible in the workplace for as long as the equipment remains in existence.

What happens with the PHSR documents upon completion of a review?

Upon the satisfactory completion of a PHSR, the employer is required to:

Ensure that the report is kept readily accessible in the workplace (including any supporting documentation). Ensure that the report is provided to their Joint Health and Safety Committee for review prior to the operation of the equipment.

What are some typical applications whereby a PHSR is completed?

The criteria that triggers the requirement for a PHSR is fairly detailed, and varies depending on the circumstances. In industry, any equipment whether new or modified, fitted with the following protective elements usually requires a PHSR:

Safeguarding devices that signal the apparatus to stop (i.e. safety light curtains, area scanning systems, two-hand control systems, etc.)

Physical barriers or safety fence that use interlocking mechanical or electrical safeguarding devices (i.e. key entry systems) Safety circuits should be hardwired or controlled by a safety PLC Safety circuits should be properly designed for the application (i.e. typically dual channel or control reliable) Safety guarding must be the correct: height, distance away from equipment, correct size openings Equipment must be fitted with a safe entry mechanism Pneumatic / hydraulic circuits must be functionally safe during power out and equipment entry situations (i.e. de-energized to prevent injury) Equipment must be designed to safely withstand load capacities Safeguards must be failsafe - tolerant of single faults that may occur

The above examples are only a select few that must be considered during a PHSR. An assessment of these types of applications would involve a review of established standards and regulations (i.e. ANSI, CSA, MOL, ISO, etc.) as well as the professional expertise and experience of the reviewer.

What are my responsibilities and obligations as an Employer?

An owner, lessee, or employer, should follow a systematic procedure when considering any piece of equipment for a PHSR. An overview of this process is illustrated in the flow chart below. It is the obligation of the employer to follow the principles of due diligence and take all necessary steps to ensure safety.

What is Due Diligence?

Due diligence is a management strategy to protect workers and prevent accidents, as well as reduce financial and legal risk. It involves the establishment and maintenance of a corporate system that manages health and safety in the workplace. In exercising due diligence, an employer is essentially showing that they have taken all necessary and reasonable precautions to avoid a particular incident. Often, in a legal sense, due diligence is used as a successful defence; however, a statutory due diligence defence does not cover all charges under the OHSA. In other words, it is important for an employer to demonstrate the use of due diligence to ensure safety, but does not guarantee immunity from the regulations of the OHSA. In cases where defences of due diligence have been successfully demonstrated, the accused party has

assessed the risk of exposure to identified hazards

implemented controls, where necessary, to minimize the risk of exposure

communicated the hazards, risks, and controls, to workers

monitored workers, work practices, and the workplace, for hazards

corrected unsafe work practices and remedied hazardous situations

An employer can facilitate the process of due diligence by hiring an outside consultant to provide assistance in analyzing equipment for inherent risks as well as performing risk assessments. MMC. will provide an employer with these types of services, in addition to relieving some of the stress and liability normally associated with equipment safety.

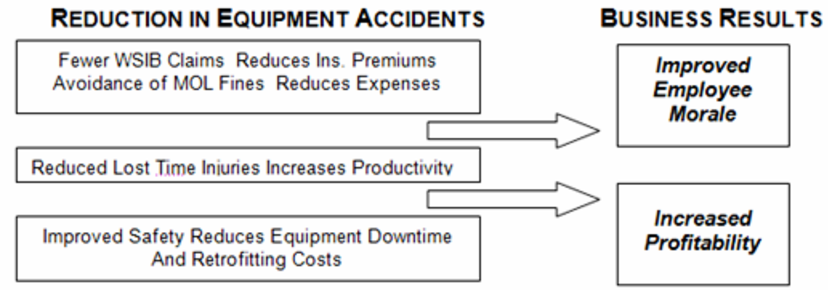

Are there any business benefits or incentives in performing PHSRs ?

While the main purpose of PHSRs is to ensure worker safety, there are certainly other benefits to consider, as seen in the illustration below.

Our Proposal

MMC is dedicated to providing businesses with the expert professional knowledge necessary to achieve compliance with all obligatory regulations and standards. We will utilize our engineering expertise in both the automotive and manufacturing industries to provide our clients with Pre-Start Health and Safety Reviews, as well as innovative design solutions.

Our goal is to provide you with all of the necessary services to assess your equipment systems for OHSA compliance, as well as design and implement the necessary changes for you to meet the applicable regulations. MMC. will not only provide you with high quality, low cost services, but will give you the confidence that your workplace equipment is safe for your employees.

The Benefits of using MMC..

MMC can work with machine builders and suppliers to ensure that your equipment is compliant before it is delivered to you.

We can support you in conducting full hazard identification and risk assessments of your new or existing equipment to determine whether it meets the necessary regulations and is safe.

We will conduct complete and thorough Pre-Start Health and Safety Reviews at a reasonable cost that is within your budget.

Our engineers are very experienced at providing safety solutions that will achieve a balance between overall cost and production effectiveness.

We put your needs ahead of our own. Many engineers are more concerned over their own personal liability and will lead you to implement excessive solutions that are unnecessary. We are committed to making realistic determinations that yield the best possible outcome for your business while achieving compliance.

We guarantee the utmost level of discretion and privacy and will not relinquish trade secrets or confidential information to anyone.

MMC will readily provide any of the above engineering and safety services for entire plants – we will devise a plan to check all of your equipment systems as an entire turn-key project that is set to a schedule accommodating your needs.

In providing effective safety solutions, you can rest assured that your workers are less likely to sustain equipment related injuries. Ministry of Labour audits are always more positive when they know that PHSRs are being provided from a competent and reliable source.

Monetary savings as a result of fewer equipment related injuries and reduced lost time in manpower.

In having us provide you with our engineering services, you will be exemplifying the process of due diligence and showing your employees that you take safety very seriously and take no short-cuts.

MCC provides Pre-Start Health and Safety Reviews (PSHSR) for large variety of machinery and equipment, such as but not limited to:

- >Robotic systems and automation

- Mechanical, Pneumatic, Hydraulic and Brake Presses

- CNC and Milling machines

- Dust collection systems

- Lifting devices

- Overhead cranes

- Balers and Compactors

- Bending, Forming & Welding equipment

- Packaging & Labeling machines

- Storage Structure Racks

- Injection & blow molding machines

- Printing presses

- Spray booths

A Pre-Start Health and Safety Review (PHSR) should be performed where the equipment, process or structure is used. The Pre-Start Health and Safety Review (PSHSR) process will be carried out in two stages as follows:

- Review the layout & design drawings for mechanical safety including guarding and protective devices and compliance with relevant codes and safety standards.

- Review the electrical drawings for compliance with the Ontario Electrical Safety Code.

- Evaluate the operating cycle and verify a safe working environment.

- Test the machine for normal operation and taking photos for the existing guarding system.

- Recommend proper safeguarding solutions that should not restrict the operation system and should meet the safety requirements as well.

- Recommend proper and reliable safety control circuits

- Provide Pre-Start Health & Safety Reviews sealed by a professional engineer. The reports shall describe all measures that should be taken to achieve compliance with the relevant provisions of Ontario Regulation 851 for industrial establishments. The report shall also include results of any inspections performed.

STAGE 2

- Follow ups prior to final compliance

- Provide final compliance safety report

- Issue certificate of safety compliance

- Post MHD-safety-approved sticker on the machine

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.

Business Process Reengineering

Business Process Reengineering involves the radical redesign of core business processes to achieve dramatic improvements in productivity, cycle times and quality. In Business Process Reengineering, companies start with a blank sheet of paper and rethink existing processes to deliver more value to the customer. They typically adopt a new value system that places increased emphasis on customer needs. Companies reduce organizational layers and eliminate unproductive activities

- Redesign functional organizations into cross-functional teams.

- Use technology to improve data dissemination and decision making.

- Refocus company values on customer needs

- Reorganize a business into cross-functional teams with end-to-end responsibility for a process

- Rethink basic organizational and people issues

- Reduce costs and cycle time

- Improve business processes and quality across the organization

Development of Policies and procedures

MMC develop high level operational policy and procedures that cover all business activities including HR departments.

The process of developing a policy or procedure begins by recognizing the need for written information that addresses a facility goal or challenge. Policies are Administrative tools that help employees attain the facility's goals. They describe what is to be done and why it is to be done. A description of the process or actions that comprise the commonly accepted ways to perform routine or repetitive tasks. Procedures are developed by administrators and are used by all personnel to help ensure that policies will consistently be carried out.The formalized and sequential process to develop policies and procedures are:

- Define the Issue, Problem or Task.

- Determine responsibility for development.

- Develop a draft of the policy or procedure.

- Review and Analyze the Policy/Procedure Draft.

- Revise the Policy/Procedure Draft.

- Conduct a Final Review and Make Final Revisions. .

Organizational and Structure Development

The Organizational Structure is the relationship among organizational unites (Divisions, Departments, Sections, units)

The HR Structure is the relationship among job holders (Hierarchy of supervision)

This service is provided for new entities structuring or restructuring of existing entities. This step is a crucial one during the entity’s lifecycle. As failure of customizing needs with corporate Governance rules will lead the entity to complete failure in achieving its objectives.

Practical methodologies comprising between international best practices, and business culture within the state of Kuwait for maintaining:

- Technical specialization

- Smooth decision making and taking Succession Plans

- Implementation of HR functions as aligned with the best practice in the field

- Applying the laws and rules in force within State of Kuwait in relation to the Company's activity

Management Audit & Assessment

MMC’s team of highly qualified auditors is able to provide you with a range of audit and assessment services which can enable your organisation to focus improvement action where it will deliver the greatest benefits.

The outcomes of a sound audit approach should be:

- Demonstrable compliance with legal and other requirements.

- Effectively managed risks.

- Significantly reduced costs.

Internal Auditing

A robust and effective internal audit programme is essential for maintaining a healthy management system. For this reason, ISO 9001, ISO 14001, OHSAS 18001, ISO 55001 and every other management system standard specify key requirements for internal auditing.

Certification auditors and regulators will examine this area with keen interest.

Assessing Suppliers & Contractors

Audit is a powerful tool for managing the risks associated with the goods, works and services you purchase. In some sectors, failure to manage such risks can lead to massive levels of avoidable cost.

We are happy to work with management system managers, project managers or your procurement function, as required.

Supply Chain Management

Our team includes quality managers and quality eng class="strong"ineers with in-depth skills and experience not only auditing suppliers and contractors, but also applying appropriate QA/QC disciplines to assess their processes and products.

Their support can make a critical difference in the sustainable performance of your supply chain.

The Certification Process

Certification couldn’t be simpler, thanks to our four stage process. The first stage is the completion of an ISO compliant manual, which can be done by one of our experienced consultants, or by yourself using our templates.

Stage two is implementation. In this step, your new manual will need to be brought into use at your organisation. Our dedicated consultant will be at hand to advise you on the best ways to do this.

Stage three is certification. To achieve your ISO certification, 3rd party certification company must visit your organisation and ensure that the processes documented in your manual are being followed correctly.

The final stage is surveillance. Your manual and processes must be checked each year to ensure your certification remains valid.

For advice or an instant quotation, please call us on +965 25712190

The 4 Stages of ISO Certification

Using our ‘keep it simple’ approach to ISO, we have simplified the certification process into four easy to understand stages.